Industrial Internet of Things

Industrial Internet of Things Specification

- Monitoring

- Remote equipment monitoring

- Network Protocols

- Supports MQTT, Modbus, TCP/IP

- Data Acquisition

- Real-time data collection

- Product Name

- Industrial Internet of Things

- Power Supply

- AC/DC adaptable

- Operating Temperature

- -20°C to +70°C

- Communication

- Wireless/Wired

- Integration

- Compatible with PLC, SCADA, and other controls

- Technology

- IoT Platform

- Usage

- To connect and monitor industrial equipment

- Security

- Multi-layer data encryption

- Material

- Standard Components and Embedded Systems

- Application

- Industry Automation

Industrial Internet of Things Trade Information

- Minimum Order Quantity

- 1 Case

- Supply Ability

- 1 Case Per Week

- Delivery Time

- 80 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Industrial Internet of Things

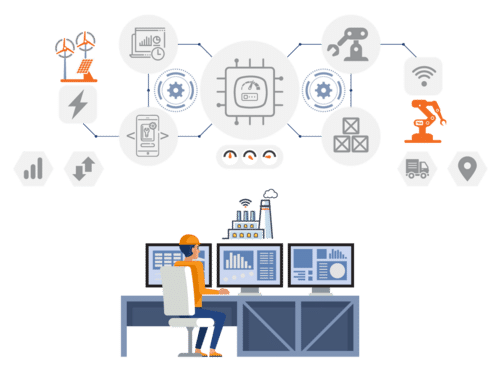

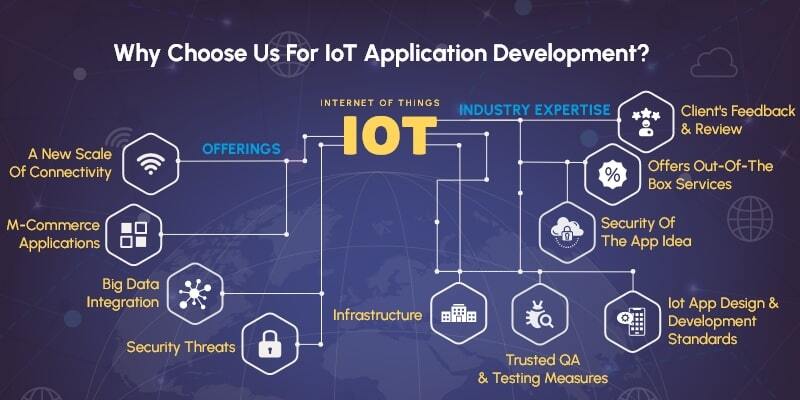

Alsystemz Solutions specializes in implementing smart IndustrialInternet of Things (IIoT) technology to help businesses connect, monitor andmanage industrial equipment. Our solutions enable seamless integration ofsensors, devices, and software to provide real-time insights into youroperations, allowing for greater control and efficiency.

IIoT System Design and Integration

Our IIoT solutions begin with a comprehensive system design andintegration process:

Real-Time Monitoring and Data Analytics

With IIoT technology, you can monitor equipment performance andanalyze data in real-time for providing valuable insights into your operations:

Smart Management and Automation

IIoT technology also enables smart management and automation,enhancing operational efficiency:

Benefits of Smart IIoT Technology

Implementing IIoT technology with Alsystemz Solutions providesseveral key benefits:

Industries We Serve

Our smart IIoT technology solutions are applicable to a widerange of industries, including:

- Manufacturing and Industrial

- Energy and Utilities

- Pharmaceuticals and Healthcare

- Transportation and Logistics

- Food and Beverage Processing

Seamless Integration for Enhanced Automation

Our Industrial Internet of Things platform seamlessly integrates with existing control systems such as PLCs and SCADA. This compatibility enables fast deployment in diverse industrial setups, ensuring real-time data transfer and centralized monitoring for effective industry automation.

Advanced Data Acquisition and Remote Monitoring

Experience continuous, real-time data collection and immediate status updates from remote equipment. The technology supports wireless and wired connections, allowing operators to monitor machinery conditions, optimize performance, and prevent downtime from virtually anywhere.

Security and Reliability You Can Trust

Multi-layer data encryption ensures that all transmitted information remains secure, even in demanding industrial environments. Our hardware operates efficiently from -20C to +70C, with AC/DC adaptable power for uninterrupted use.

FAQ's of Industrial Internet of Things:

Q: How does the Industrial Internet of Things platform help in remote equipment monitoring?

A: The IIoT platform enables real-time data acquisition and remote monitoring by connecting to equipment through both wireless and wired networks. Operators can track operational status, detect abnormalities, and receive alerts from anywhere, increasing responsiveness and minimizing unplanned downtime.Q: What network protocols does this IIoT solution support for integration with existing systems?

A: Our solution is compatible with widely used industrial protocols such as MQTT, Modbus, and TCP/IP, making it easy to connect with PLCs, SCADA systems, and other control hardware present in most industrial environments.Q: When can this IIoT platform be deployed in an industrial setting?

A: This system can be implemented at any stage in a project lifecycle-whether retrofitting an existing facility or integrating into newly developed processes-offering flexibility for manufacturers seeking to modernize their operations.Q: Where is the Industrial Internet of Things solution most effectively applied?

A: The IIoT platform excels in industries requiring automated monitoring and control, such as manufacturing, utilities, process plants, and infrastructure. Its robust design ensures reliable performance across diverse environmental conditions.Q: What is the typical process for setting up this IIoT system?

A: After assessing your existing infrastructure, our specialists help integrate the platform with current PLC, SCADA, or control systems. Devices are configured to support relevant protocols and communication methods (wireless or wired), followed by system calibration and security setup.Q: How do users benefit from real-time data acquisition in their operations?

A: Real-time data collection provides actionable insights into equipment health and operational efficiency. This enables predictive maintenance, reduces downtime, increases safety, and optimizes resource allocation, ultimately boosting productivity.

Price 35000 INR/ Case

- Minimum Order Quantity

- 1 Case

- Supply Ability

- 1 Case Per Week

- Delivery Time

- 80 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email